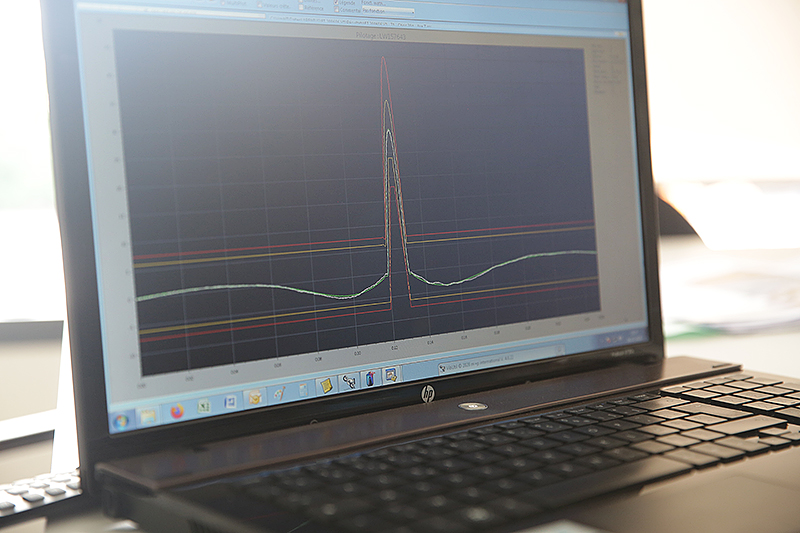

Shocks testing

The purpose of mechanical impact tests is to determine the ability of components, equipments or other products to operate without degradation, to resist mechanically and structurally when subjected to repetitive shocks or not. These tests are commonly associated with vibration tests. The most common tests are half sine mechanical shocks, final or initial point sawtooth shocks, trapezoidal impacts shocks, shock response spectrum (or SRC shocks), etc.